Punching ahead with metal fabrication investment

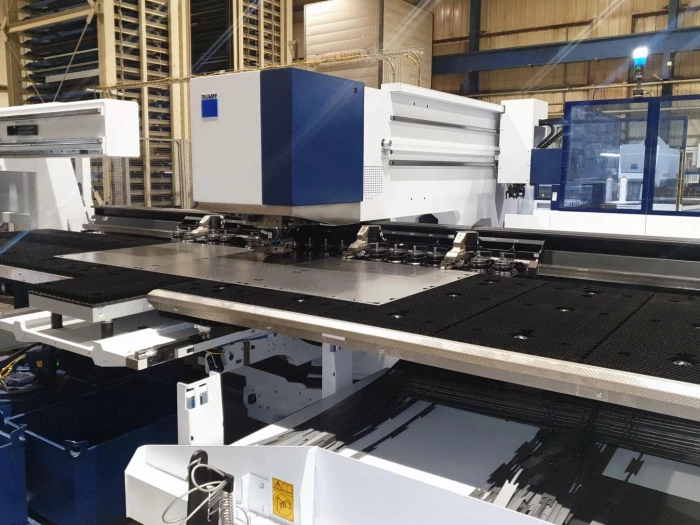

KMF Precision Sheet Metal has installed a new TruPunch 5000 CNC punching machine at their sheet metal fabrication site in Staffordshire.

The investment follows multiple new machine acquisitions, including a new TruBend 5130 press brake, bead blast unit and six additional welding bays. It keeps the company on track to achieve its '2021 Anniversary Target' – of £50 million turnover when the company turns 50 years old.

Established in 1971, KMF Precision Sheet Metal is a privately-owned business that is part of the KMF Group. The 350+ employee precision fabrication company is based at a purpose-built 160,000 sq ft facility in Newcastle-under-Lyme.

The company processes a wide range of sheet metal materials and thicknesses, from prototype quantities up to batch sizes of thousands. KMF partners with ambitious OEMs from many sectors from energy, electrical, security and medical.

The decision to replace an existing 10-year old machine with a new TruPunch 5000 improves productivity and maximises automation. The metal punching machine boasts both a 'Linear Tool Store' and 'SheetMaster Automation' and delivers significant speed and reliability benefits.

The CNC punching machine is now hard at work punching a multitude of custom precision metal components.

Terry Stanway, KMF Director, commented: "The new TruPunch 5000 is another important step in KMF Group's continual strategic factory investment plan, which focusses on cost reduction by targeted automation and capacity enhancement to support growth, and maximum flexibility to better support the demands of our diverse customer base".

According to Trumpf, the TruPunch 5000 sets high standards in terms of productivity, process reliability and flexibility. For instance, backlash-free drives enable fast axis acceleration while the high rotational speed of the C-axis enables high-speed tapping as well as the productive processing of complex contours. Thanks to the powerful hydraulic drive, it is possible to punch at up to 1,600 strokes per minute and mark parts at 2,800 strokes per minute.

Let us ease your workload! We deliver value-added metal fabrication services to large OEMs that require reliable, high-quality and flexible metal manufacturing from design to delivery. Contact us today to see how we can improve your sourcing process.